Categories

Contact Us

- No.2 Chunqiao Road, Changzhou 213127, Jiangsu, China

-

Contacts:Tommy : 0086-15851966156

George: 0086-13196756672 -

E-Mail:

All products

QX02 Coil inserting machine (servo/no indexing)

Product Details

Inquiry Now

| Description | QX02 Coil inserting machine (servo/no indexing) |

| Stator stack height | 5mm-130mm |

| Max. Stator O.D. | φ160mm |

| Stator I.D.range | φ17mm-φ110mm |

| Displacement of oil pump | / |

| Air pressure | 0.5-0.8MPa |

| Power supply | 380v/ 50Hz Three-phase four-wire |

| Power | 2.5Kw |

| Dimension(L*W*H) | 1500mm * 740mm * 1600mm |

| Weight | ≈1000kg |

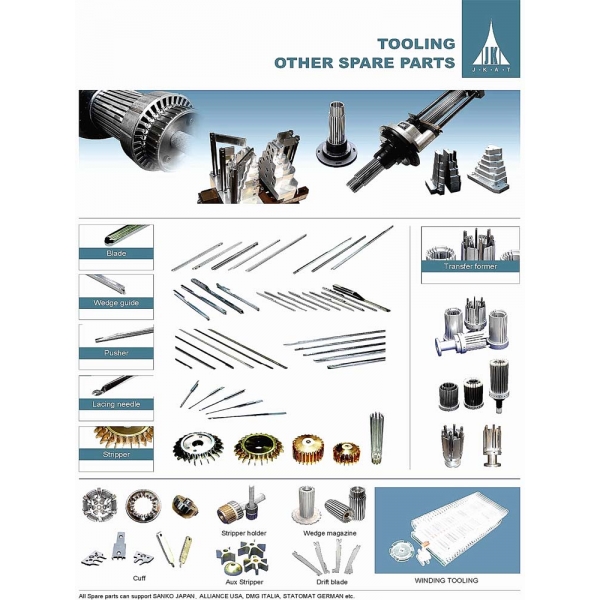

The coil inserting prcoess is the most important process in the manufacture of a stator for an electric motor. The coil insertion tool is the key part of coil inserting machine. In order to keep the coil inserting smoothly, we design and manufacture various kinds of insertion tools with absolutely high quality, well resistent.

This machine conducts gang control to inserting main shaft, wedge paper feeding shaft and wedge magazine indexing shaft through PLC control system assembly, cooperating with intelligent human-machine communication system. It conducts enamelled wires insertion, slot wedge cutting and moulding, also the wedges insertion into the stator slots when coil insertion, which completes the single/multi phase coil insertion and slot wedge insertion at one step. The machine has the advantages of even wire push torque, stable moulding of slot wedge, high production efficiency, low cost, easy and reliable use and maintenance.

Adopts AC servo motor system as source of active force, alternating frequency motor as wedge punch power;

Adopts Chinese/English HMI operating control, and has function of breakdowns self-diagnosis;

Adopts stepper motor for wedge paper feeding, could each slot set by slot skipping, wedge self-decides overall length feeding, cutting off, punching to shaping, free set of wedge inserting slot and wedge numbers;

Tact time≤25s/phase(auxiliary time not included);

Has special control switch for debugging;

Has pre-deceleration function for wedge punching and coil inserting;

Free set of push up height and stop time at the HMI;

Industrial PLC: MITSUBISHI from Japan;

Servo motor and controller: MITSUBISHI from Japan; Sensor elements: OMRON from Japan.

-

*Subject:

-

Your Name:

-

Your Phone Number:

-

*Your E-Mail:

-

*Content:Note:HTML is not translated!

TRIPHASE MOTOR SOLUTION-156x156.jpg)

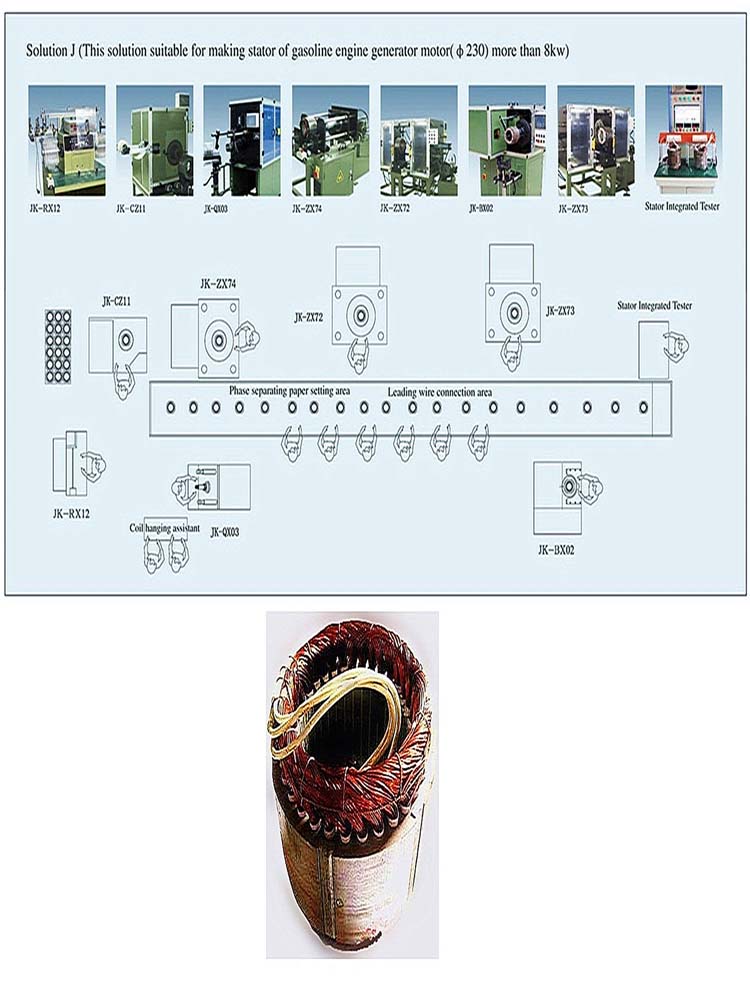

GASOLINE ENGINE GENERATOR MOTOR SOLUTION-156x156.jpg)